ELECTRICITY & ELECTRONIC

4

CLEANING & PAINTING

2

QUALITY CONTROL

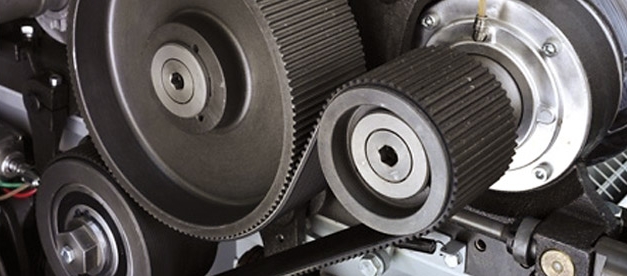

ASSEMBLING

5

3

DISASSEMBLY & ANALYSE

1

Before its shipping, the machine is controlled by our technical staff specialized in reconditioning. When the control is done and validated, the machine is transferred to our internal test centre to be tested in a real working situation with leathers

All the electric and electronic parts are entirely changed for the ultimate technological criteria, in order to answer to the ultimate European safety norms and to update the machine as the ultimate version we produce

We make the reconditioning of our machine with the genuine plans and the assembling is made through the same quality process as for our new machines

After its analyse, parts in perfect functioning estate are transferred to the booth of cleaning by sand for a complete maintenance, before being printed as new, in order to guarantee its long life time

The machine is entirely dismounted. Each part is separated, dismounted and accurately examined. Parts which present any defect or imperfection are automatically separated and changed for new material, as all the consumption spare-parts

In order to satisfy the needs of all our customers, we have our own department specialized in the reconditioning of our second-hand machines. Our reconditioned machines offer the same working value as our new machines and have a complete year of guarantee, proof of a complete and quality job.

RECONDITIONED

MACHINES