.jpg?v=1ckq8f5)

A LITTLE HISTORY...

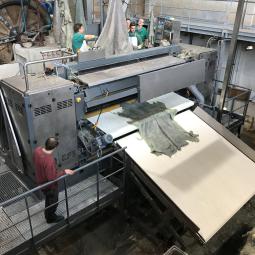

The through-feed fleshing concept has been invented by MOENUS TURNER in 1973 with the model 473. Still nowadays this machine can be seen working in numerous Tanneries worldwide due to the fact it was manufactured in cast iron, just like the new model PECARNA now marketed.

.png?v=1ctcbk8)

_1.png?v=1ctf9jd)

_4.png?v=1ctmr5u)